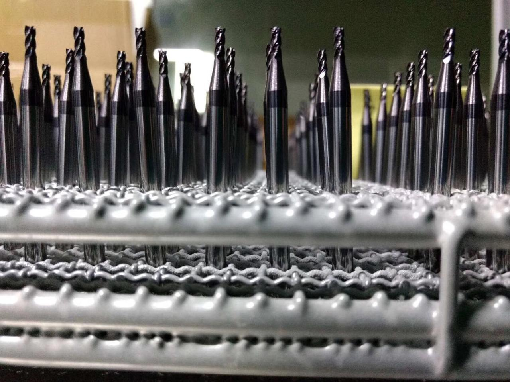

Metal Cutting Tools and Drills Application

Magnetron sputtering technology can be used to coat metal cutting tools and drills with hard and wear-resistant coatings, such as titanium nitride, titanium carbide, or diamond-like carbon. These coatings can improve the performance and durability of the tools and drills, as well as reduce friction and heat generation. It is widely used to produce coatings for metal cutting tools and drills, such as drills, mills, knives, and other tools with sharp edges.

Some of the common coating materials used for metal cutting tools and drills are titanium nitride (TiN), titanium carbide (TiC), titanium aluminum nitride (TiAlN), chromium nitride (CrN), and diamond-like carbon (DLC). These materials have high hardness, low coefficient of friction, high thermal stability, and good chemical inertness. They can also provide different colors and appearances for the tools and drills.

Magnetron sputtering technology has many advantages over other coating methods, such as chemical vapor deposition (CVD) or electroplating. Here are some of the key advantages:

-

Highly Controllable: Magnetron sputtering allows for precise control over film composition, structure, and thickness1. This level of control is essential for applications requiring specific material properties.

-

Environmentally Friendly: It typically uses inert gases and produces less waste compared to other techniques. This makes it a more sustainable option for large-scale industrial processes.

-

Low-Temperature Process: Sputtering can be performed at lower temperatures, which is beneficial for temperature-sensitive substrates. This avoids high-temperature damage that might occur with other methods.

-

Better Step Coverage: It offers better step coverage, which is the ability to coat surfaces evenly, including those with complex shapes and high aspect ratios. This is crucial for uniformity in coating applications.

-

Less Plasma Damage: While some plasma damage can occur, it is generally less than that caused by other methods, such as E-beam evaporation. This helps maintain the integrity of the substrate.

-

Versatility: Magnetron sputtering can be used to deposit a wide range of materials, including metals, insulators, and semiconductors. This versatility makes it suitable for various industries and applications.

In Summary, magnetron sputtering technology has a high deposition rate, which can reduce the coating time and cost. It also operates at low temperatures, which can avoid thermal damage or distortion of the substrate. Moreover, magnetron sputtering technology can produce uniform and precise coatings with good adhesion and conformity to complex shapes.These advantages make magnetron sputtering a preferred choice for many applications in electronics, optics, and surface engineering, where precise and high-quality coatings are required.