0086 13717128825

-

Home

-

About US

-

Products

- Rotary magnetron

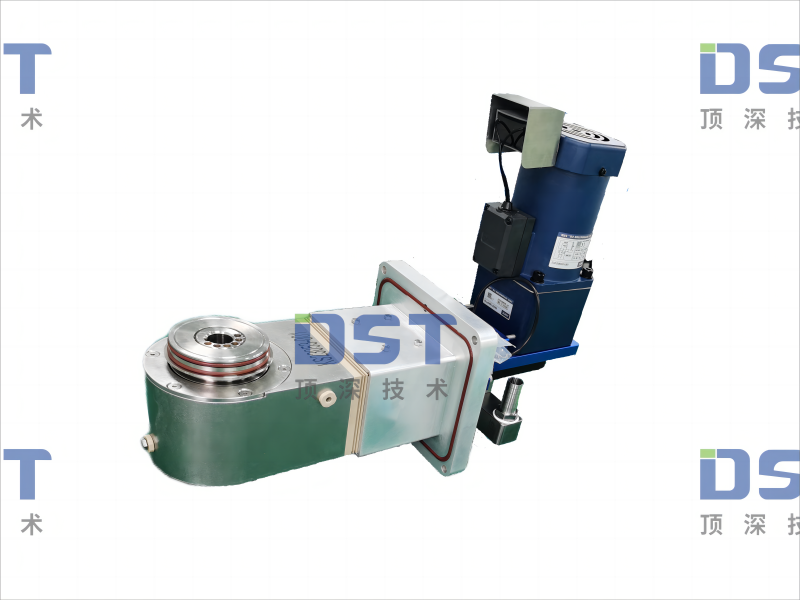

- External mount(side-mount)

- External mount(lid-mount)

- Pivotal driving(vertical-mount)

- End block

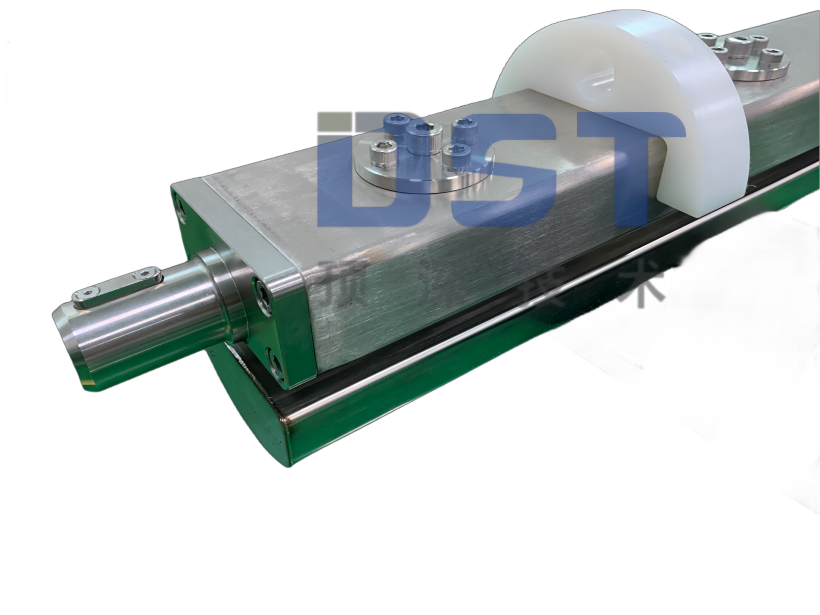

- Magnet Bar

- Planar magnetron

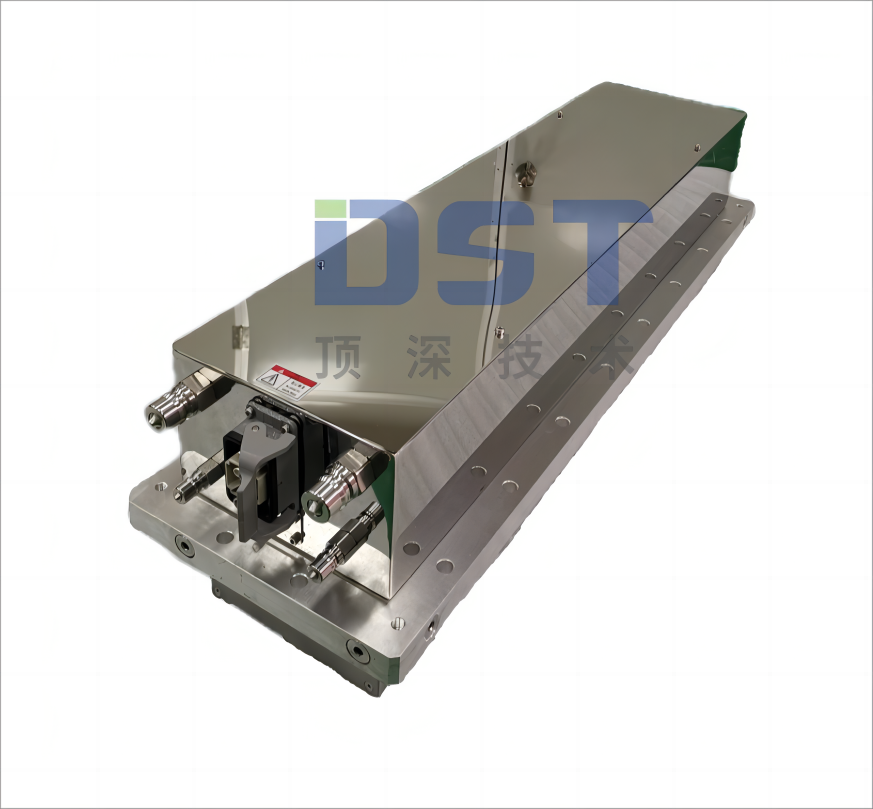

- Planar Rectangular

- Parts

- Gas Pipes

- Wear Parts

- Tools

- Laser Pointer and Seat

- Leak Detect Meter

-

Download

-

Contact US

-

Home

-

About US

-

Products

- Rotary magnetron

- External mount(side-mount)

- External mount(lid-mount)

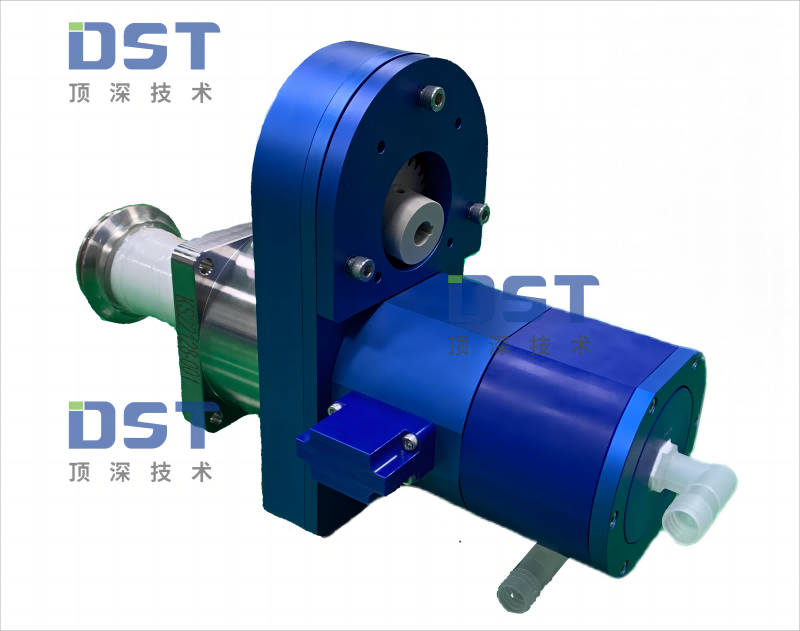

- Pivotal driving(vertical-mount)

- End block

- Magnet Bar

- Planar magnetron

- Planar Rectangular

- Parts

- Gas Pipes

- Wear Parts

- Tools

- Laser Pointer and Seat

- Leak Detect Meter

-

Download

-

Contact US

-

End block integrated angle scale for magnet bar direction adjustment

High accuracy easy adjustment and wide angle adjustment

넶31 2023-10-28 -

Solar energy absorb with Perovskite solar module

Perovskite solar cells are a new type of solar cells that use perovskite as the active layer. DST’s magnetron source has been verified in this industry with an overwhelming market share in China.

넶26 2023-10-27

Highlights

F A Q

DST's Magnetron sputtering is widely used in the automotive industry to improve the quality and safety of the vehicles by coating automotive glass with various materials to enhance its thermal, optical, and mechanical performance.

Automotives Glass

Thick Cu Film coating is one of the serveral main product applications. 80% share of sold PVD coating system produced by our cooperating manufacturers from China, are currently implemented in high volume productions of Thick Cu Film rolls.

Roll to Roll Web Coating

Magnetron sputtering is used to coat metal cutting tools and drills with hard and wear-resistant coatings, such as titanium nitride, titanium carbide, or diamond-like carbon. It will improve the performance and durability of the tools and drills, as well as reduce friction and heat generation.

Metal Cutting Tooling & Drills

Perovskite solar cells are a new type of solar cells that use perovskite as the active layer. DST’s magnetron source has been verified in this industry with an overwhelming market share in China.

Solar Energy Absorb Coating

Application

Products

-

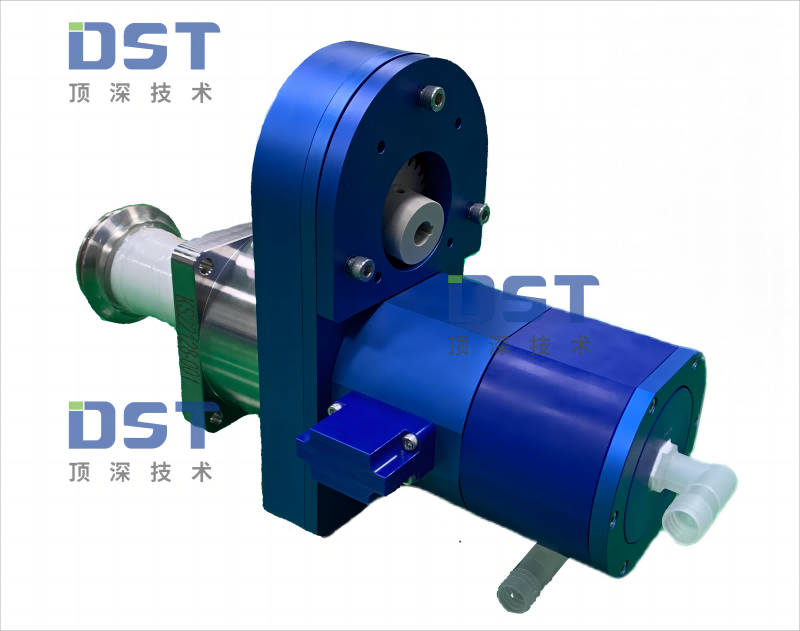

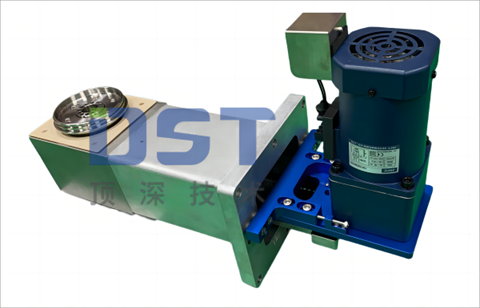

External mount Rotary Magnetron Source (side-mount End Block)

This is another sample design of side-mount custom designed End Block by DST

Please consult our distributors for other design of side-mount type of End Block¥ 0.00Buy Now

-

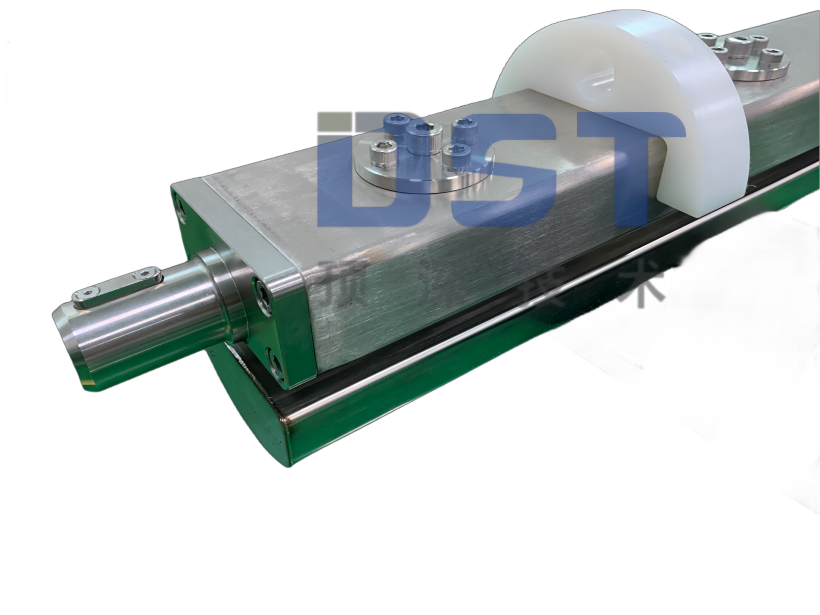

Magnet Bar for Rotary

Magnetic uniformity multi-points adjustable

Bespoke magnetic field design

Seamless encapsulation not water exposed¥ 0.00Buy Now

-

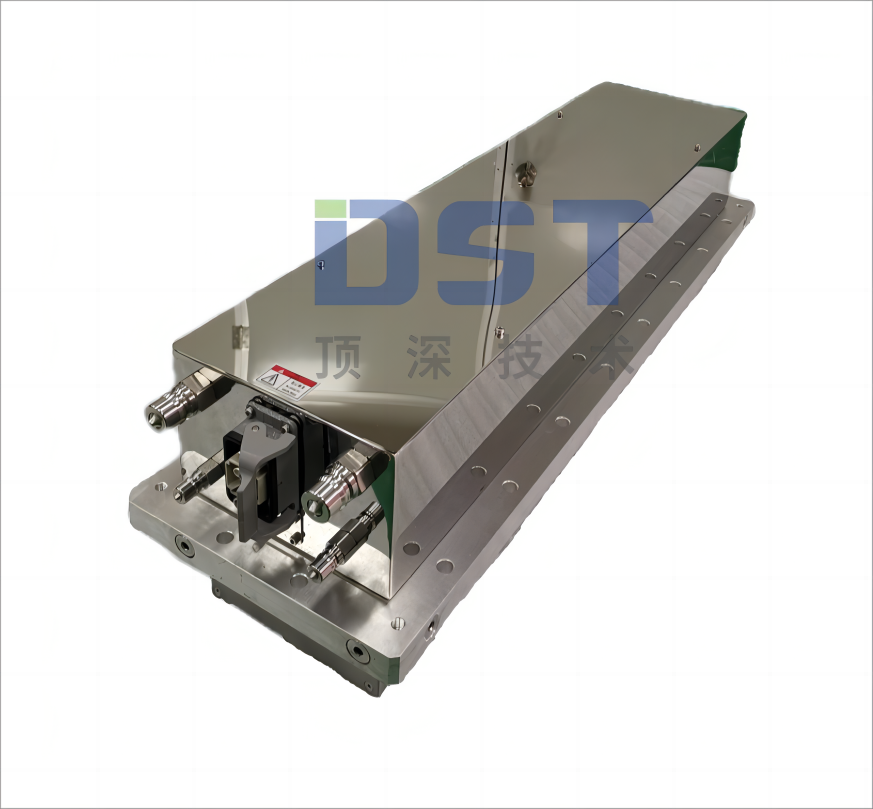

Planar Rectangular Magnetron Source

Bespoke magnetic field design

Patented anode cold water design

Gas distribution adjustable

Magnetic field strength or balance adjustable¥ 0.00Buy Now

-

External mount Rotary Magnetron Source(lid-mount)

100% filled with cold water, 100% blew down, excellent cooling effect, high process power;

Shaft seal is specially designed with special compound materials, stable rotation significantly improve process stability;

Unique inner conductivity structure and compound material, maintain resistance as low as 0.6Ω, process more stable, high coating quality;

Bespoke water velocity design, as big as 80L/min;¥ 0.00Buy Now

-

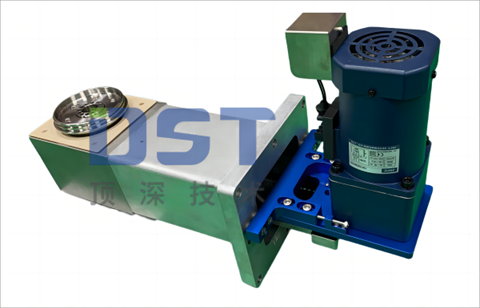

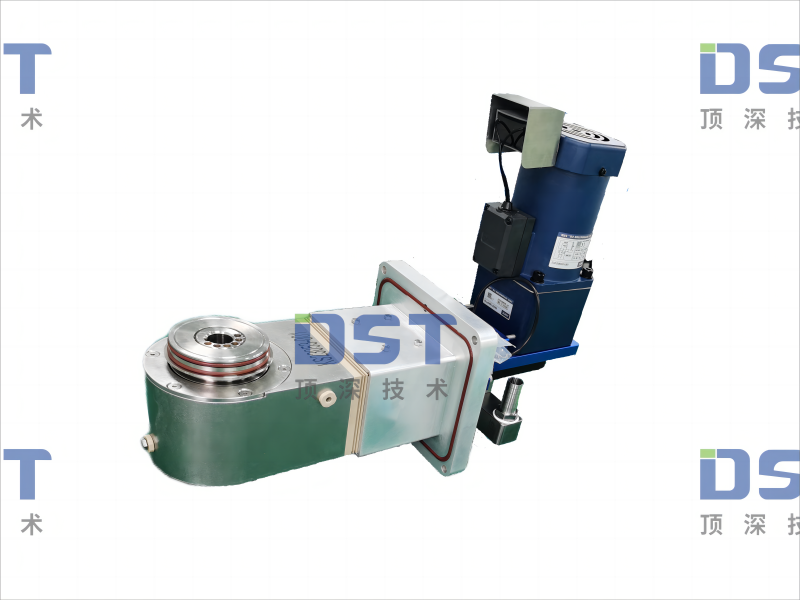

Pivotal Magnet Bar Vertical Rotary Magnetron Source

Great cooling effect 100% fill up cold water

High-purity carbon brush, resistance less than 0.6 Ω

Specially designed driving system can greatly improve the motion stability

Target exchange without disassembling the end support assembly¥ 0.00Buy Now

-

External mount Rotary Magnetron Source (side-mount)

Custom size available

Water 100% fills the cathode

Excellent power transfer, resistance as low as 0.6Ω

High vacuum and water shaft seal exclusively designed

Cold water velocity up to 80L/min¥ 0.00Buy Now

About Us

Dongguan Dingshen Tech Co., Ltd. was established in 2019. At DST, we specialized in designing and manufacturing core components for PVD vacuum coater, our main products are rotary magnetron source, planar magnetron source and ion source, etc.

Our company philosophy is "Leading technology, outstanding services." Since our establishment, we have been carring with our determination in delivering advanced technology and sincere services that meet the needs and expectations of our customers.

Q:1.What kind of magnetrons can you provide?

A: At present, we mainly produce rotary magnetrons(cylinder) and planar magnetrons;

Q:2.Can you send me a price list?

A: For all of our magnetrons, they are customized based on different requirements like process requirements, magnets design, exterior inner and outer structure and dimensions requested, etc. So it's really difficult for us to make a price list. If you can share your detailed requirements, we'll see what offer we can provide.

Q3:What sort of application could your magnetron source be used for?

A: Our magnetron sputtering source is essential on the deposition of 1) large area architectural and automotive glass for AR, Low-E, Heat Insulation, Solar Control functions; 2) Displays & Touch panels; 3) Solar thermal systems; 4) Photovoltaics and Precision Optics; 5) sensor, Mobile Devices and MEMS, MOEMS;

Q4:Can l visit your factory before we place an order?

A: welcome to visit our factory,we are every pleased if we have the chance to know each other more.

Q:5.What's the lead time for a regular order?

A: For orders, the standard lead time is 90 days and this time can be shorter or longer based on the different model design, requirements and quantity.

FURTHER FIND OUR ADVANTAGES

Request for Information